Research and innovations

In line with our ambition of being Smart in Flow Control, SAMSON is continuously driving technical, business and organizational innovations. Our activities are focused on bringing our customers benefit and supporting their production processes to ensure process safety, reliability and a high availability. Our customers' processes serve as the benchmark for our innovations in digitalization, simulation technology, design and instrumentation and controls. This is why we are developing smart systems that help to further optimize process automation.

SAMSON has a long tradition of developing innovative products and services and involving staff from all areas of the company in these processes. We rely on the experience and demands of our customers when generating ideas, drafting concepts and developing products. To the same extent, we include market research, the latest technical developments and new technologies in our activities. Mastering the theoretical fundamentals of physics, fluid dynamics and material science is essential when turning an idea into a high-quality product for process automation. We are convinced that conducting research in close cooperation with partners is the key to developing successful, innovative, prime-quality products. Technology leadership is our goal. We rise to the challenge of matching our customers' operating requirements in the long term.

More than 200 technicians and engineers work at the different SAMSON research and development facilities. It is their specialist knowledge, know-how and creativity that we need to create products. Major fields of activity include:

- Valves and actuators

- Automation and integration technologies

- Valve accessories and sensors

- Cyberphysical valves and systems

- Pilot development

- Investigating the physical and technical fundamentals relating to control valves

- Conducting R&D projects in cooperation with universities

Excellent staff training forms the basis of excellent products. SAMSON has always been aware of this. As a result, we offer young people the opportunity to do their vocational training at our company or to join us for job placements and internships. As part of our university cooperations, we take in students writing their bachelor or master theses.

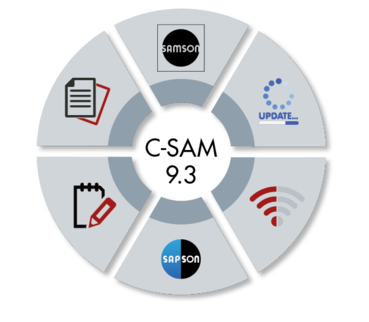

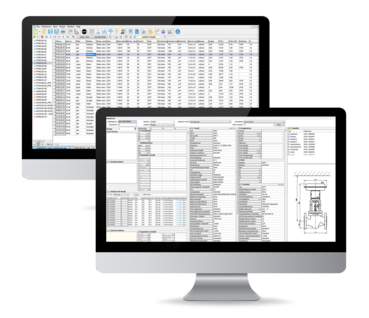

c-SAM is the valve sizing software developed by SAMSON for exact valve and actuator sizing. Our sales staff in Germany and abroad can rely on the quality of the tool. We guarantee to find the right valve and the right actuator for every application by:

- Continuous development of the sizing algorithms the software is based on

- Complete implementation of all sizing fundamentals and flow coefficients

- Continuous programming of add-on sizing modules

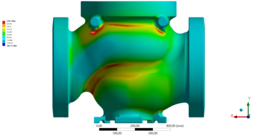

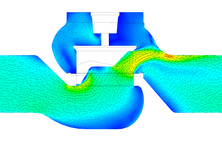

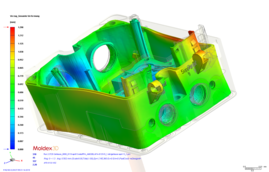

Naturally, simulations are part of product development at SAMSON. We use them at an early stage in the development process to obtain an in-depth analysis of the different physical properties of a new product. We create prototypes and put them through their paces by performing thorough function and wear tests under real-life conditions in our ROLF SANDVOSS INNOVATION CENTER. It is our ambi-tion to provide our customers with products that meet different requirements and achieve high levels of reliability already when they are introduced into the market.

SAMSON employs various simulation methods, simulation tools and our own simulation facilities depending on what is required in the development process. In addition to the circuitry and control loop simulations we perform as part of our electronics development, we use other wide-spread procedures, such as:

You can find more information about our simulation service in our

The ROLF SANDVOSS INNOVATION CENTER (RSIC) was opened in November 2017. It is the state-of-the-art R&D center for valve engineering and a place where people from all across the world interact. Our goal is to bring together partners and customers in our facilities to jointly develop, investigate and test valves, valve accessories and digital applications. The modular, networked measuring and automation system provides the following features:

- Automated performance of tests

- Central and distributed monitoring of tests

- Acoustic and real-time tests

- Integration of neural networks

- Data visualization, analysis and aggregation

- Hardware-in-the-loop (HIL) to simulate customer-specific process conditions

- Investigations into distributed intelligence

- Plant diagnostics

Facts and figures

Building

| Plot area: | 3265 m² |

| Floors: | 3 (plus basement) |

| Gross total area: | 9050 m² |

| Usable area: | 7000 m² |

| Building volume: | 53000 m³ |

| Max. height: | 22.3 m (25 m including silencer) |

| Steel: | 1100 t (76,5 km) |

Plant engineering

| MEP lines: | 4000 m |

| Electric cables: | 40 km |

| Data and ICA cables: | 50 km |

| Water tank: | 400 m³, 78 t |

| Pipeline network: | 2070 m |

| Signals used (I/O): | 1673 |

| Valves installed: | 253 |

| Pumps installed: | 8 |

| Total power installed: | 5.5 MW |

![[Translate to English:] Prototypenbau [Translate to English:] Prototypenbau](/fileadmin/_processed_/2/3/csm_prototypenbau_06_ef71f4226f.jpg)