Maintenance-friendly valves in combination with SAMSON valve accessories proven in the field meet all requirements placed on them. Their modular design makes them flexible for a wide variety of applications concerning possible actuation (self-operated, pneumatic or electric), pipeline interfaces (flanges or sandwich-style design) and control signal (analog or digital). Their quality and easy-to-service design have a positive impact on plant availability. Cleverly devised components, such as the SAMSON SteamUnit or the SAMSON Type 5724-8 Electric Actuator with Process Controller, help optimize essential process stages and increase the cost-effectiveness of plants by reducing energy consumption.

Staff at SAMSON possess a wide-ranging knowledge in valve engineering and different processes. Thanks to the worldwide sales and service network, they can support customers on a local basis.

Production of raw materials

In many factories around the globe, SAMSON control valves are used to manufacture raw materials for the tire industry. Such plants include those to manufacture synthetic rubber (e.g. BR and SBR), silicon dioxide and various additives.

Mixing of materials

Achieving the right mixing temperature is just as important as finding the right mixture of raw materials. In many processes, the temperature during mixing must be reached quickly, yet not rise in an uncontrolled way.

Extrusion

SAMSON's product portfolio includes the right equipment to heat extruders with steam. SAMSON has many years' experience in controlling steam used as the energy supply.

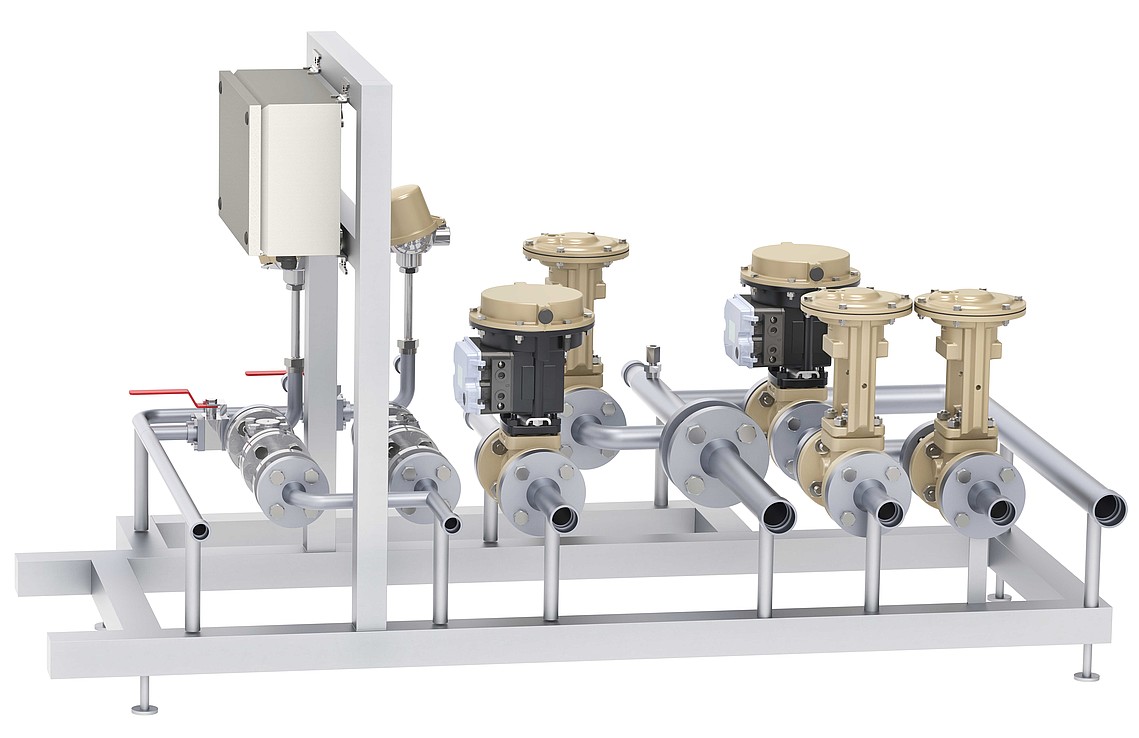

Electric actuators with process controllers

The SAMSON Type 5724-8 Electric Actuators with Process Controllers are designed especially for temperature control loops. They come with two integrated PID control modules to implement differential temperature, override and cascade control. Together with a valve, they form an autonomous, compact control unit requiring no additional external controllers.