Optimization of Contracted Heating Systems

Exemplified by GASAG Solution Plus GmbH

As a company active in district heating and cooling, GSP aims to achieve greater efficiency in its supply operations and wants to considerably reduce its CO₂ footprint. And all this without lowering the level of comfort for consumers.

Pilot plant

A residential complex built in the 1980s was selected to serve as a pilot project. It comprises a 2.6 MW local heat supply network and twelve transfer stations.

In addition to heat generation, GSP is also responsible for heat distribution and controlling the heating circuits in the transfer stations. Heating controllers from the TROVIS 5500 Automation System made by SAMSON are used in this heating network.

In a first step, the systems were optimized manually by adapting the parameters. This turned out to be a huge success already. In some cases, the flow and return temperatures could be lowered by up to 10 K.

Procedure

A temperature reduction of 10 K was the best improvement attainable with the static, manual approach. As a result, a digital procedure had to be found to maximize the potential savings.

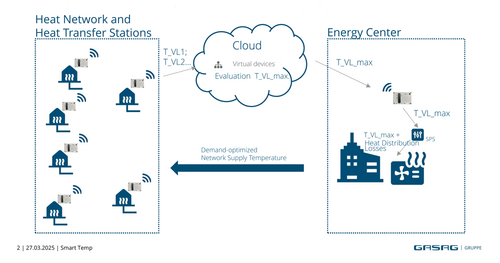

This job was done by a special machine learning program. The program is integrated into SAMSON's web-based SAM DISTRICT ENERGY solution. Historical data as well as live data and weather forecasts from the SAMSON computing cloud are processed and used for AI training. The AI algorithms learn based on the meter and controller data to reduce the heat demand accordingly.

This leads to a continuous optimization of the set point. Contrary to manual optimization, the AI-based approach can prevent insufficient heat supply and respond quicker, particularly in the transitional seasons. The system is also faster at detecting that no heat is being tapped.

Conclusion

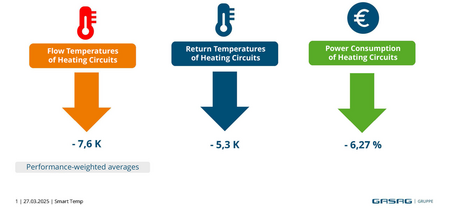

The intended objectives were reached with the first pilot project already. Further reductions of the flow and return temperatures became possible at the transfer stations optimized so far.

The heat output was rarely higher than with the static procedure, yet no insufficient supply or tenant complaints occurred. The temperature reduction is partly smaller than with the analog optimization procedure, but the procedure can also be applied without performing an initial optimization.

The highest savings were identified at outdoor temperatures between +1 and +10 °C. In these conditions, average reduction potentials from 7 to 8 K exist. At higher and lower outdoor temperatures, the identified flow temperatures could be around 5 to 6 K lower.

Four key results:

- The flow temperature could be further reduced by up to 8 K (this is a benefit efficiency-wise, particularly for heat pump systems)

- On average, the heat output depending on the outdoor temperature came down by around 6 %.

- No tenant complaints due to insufficient supply

- No manual intervention à Fully automated optimization process

Outlook

At the next stages, optimization will be extended to the entire local heat supply network: the flow set point temperatures, which are actually required, will be fed to the heat generators through SAM DISTRICT ENERGY to further reduce the network temperature and match real-life demand. The lower temperatures will be handed down from the consumers to the generators. In addition, optimization using the Smart Temp function is to be applied to further transfer stations and local heat supply networks.

Inspired by what you've seen?

Looking for a solution tailored to your needs? Discover how SAM DISTRICT ENERGY can transform your energy management. Explore the full potential of our innovative digital solution and unlock real value for your business.

Our experts are ready to guide you – get in touch today!

About GASAG Solution Plus GmbH

GASAG Solution Plus GmbH (GSP) specializes in the implementation and management of custom supply solutions in heating and cooling systems based on a contracting model: in residential areas and industrial plants, in office buildings and hospitals. In total, around 150 staff members ensure 410 GWh in heat supply.

In Berlin, Germany, the majority of systems is installed in residential communities. The required heat is generated using CHP plants and boilers as well as heat pumps fed by geothermal systems, PVT collectors or waste heat. Generation often takes place at central locations from where the heat is distributed to consumers within the communities or in small local heat supply networks.